Using machine learning to improve semiconductor production

15 November 2021 | By: Anurag Sharma | 2 min read

A shortage of semiconductors has disrupted supply chains around the world. A new PhD project in Singapore hopes to increase the reliability of manufacturing and help future supplies.

Last month the Straits Times in Singapore reported that manufacturers of semiconductors were stepping up their talent development amid a "rampant global demand for chips that shows no sign of slowing down."

Semiconductors - also known as integrated circuits or chips - are a key component for many supply chains around the world. They can be found in cars, white goods, smartphones, games consoles and more.

Given the importance of semiconductors in global supply chains, it makes sense that companies are looking to improve the reliability of their manufacturing.

Here in Singapore, we are working with GlobalFoundries, a major international manufacturer of semiconductors. We have established a new PhD project that aims to improve the reliability of the process to manufacture integrated circuits. The project is funded by the Singapore Economic Development Board and GlobalFoundries.

How are semiconductors made?

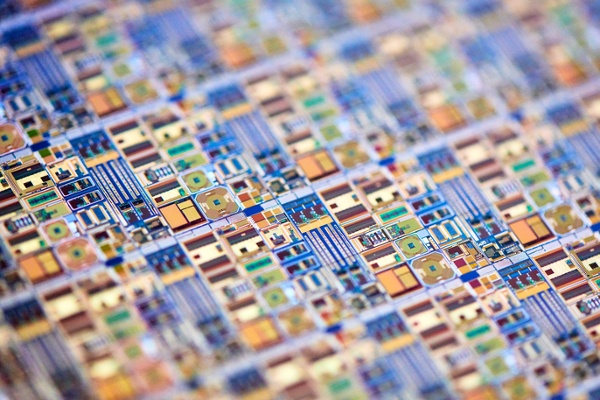

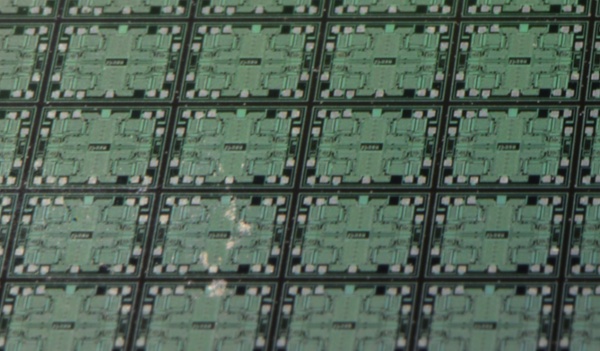

The chip design is fabricated onto a wafer of silicon. A complex process builds up many small blocks of semiconducting materials, each block is called a die.

Each wafer may contain a large number of identical dice that are separated towards the end of the process to make individual chips at large volume.

A close up of a silicon wafer showing the layout of the dice (by Laura Ockel on Unsplash)

A close up of a silicon wafer showing the layout of the dice (by Laura Ockel on Unsplash)

During the wafer fabrication, sensors are able to generate information about the chemical layers in the dice and the uniformity of the wafer. This data can show whether the wafer meets the required quality standards.

At the post-manufacture stage, there is also an electrical test that indicates whether the dice on the wafer are of an appropriate quality standard.

These measurements provide an overall measure of quality compliance at the end of the manufacturing process.

Real-time predictive quality assurance data in chip manufacture

Our project is applying machine learning techniques to the data coming from the quality checks. The aim is to provide more precise quality assurance by, for example, pinpointing quality issues with an individual die on the wafer.

Our data analysis from the post-manufacturing test aims to normalise the data set. Normalising means we align the values from all of the tests to a common scale. Having normalised results from many tests, we can build a model of the fabrication process.

We can then use the model to make predictions about which parts of the fabrication process may cause quality issues. In this way, extra control measures can be implemented into the manufacturing process to reduce the number of defective dice on the wafer.

The use of machine learning to provide real-time predictive quality assurance data in chip manufacture will improve the reliability of the process and result in less wastage. This is an important piece of research work for GlobalFoundries that manufactures chips in very large quantities.

Our partnership with GlobalFoundries

I have a long-standing connection with Jonathan Ong at GlobalFoundries. It started when GF offered internships to Newcastle University and SIT undergraduate engineering students. Jonathan was very impressed with the skills of the intern students and this led to conversations about collaboration at PhD level.

GlobalFoundries is one of the largest producers of semiconductors in the world. They have fabrication plants in North America, Europe and a major presence in Singapore with a fabrication plant, research and design centre, and regional office. In this high-tech environment, there are many opportunities for research projects.

Jonathan and I work with an excellent team for the project including:

- Dr Cheng Chin, Reader in Intelligent Systems Modelling and Design, brings expertise in electronics and artificial intelligence

- A high-achieving graduate, Martin Lim, was recruited as a PhD student for the project.

The project is progressing successfully and we are exploring more collaborative research projects between Newcastle University in Singapore and GF.

Find out more

- Dr Anurag Sharma - Assistant Professor in Electrical Power Engineering

- How Newcastle University works with business

- Header image: taken by John Donoghue